You might know the name padauk by the splash it makes in the carpentry world. Known for its durability and beautifully marbled grain, it’s becoming quite popular for all kinds of projects.

But can you use padauk for cutting boards? Padauk is a relatively heavy hardwood, which makes it one of the best choices for cutting boards. Most other types of woods used to make cutting boards either come up short in durability or can’t handle the wear and tear in the kitchen.

In this article, let’s learn more about padauk wood and why it’s all the buzz, especially as a solution for making cutting boards.

What Is Padauk?

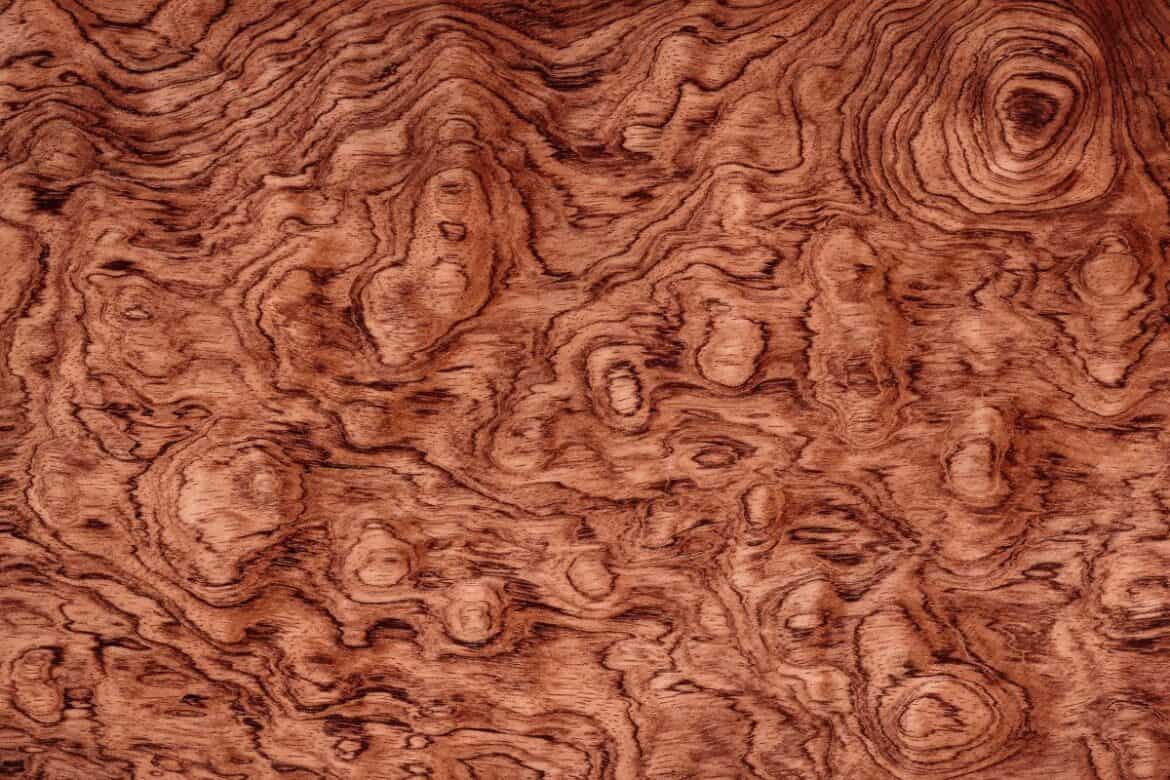

Padauk is a hardwood that can be found in various species of Pterocarpus in Asia and Africa. It is known for its durability and strength, and its signature reddish color is the reason padauk is often confused with rosewoods.

The African padauk is the most popular type of padauk wood. It is also often called Vermilion due to its reddish-brown color. It has a coarse and open texture, and its heartwood can be pale or deep brown color.

Padauk is a popular choice in the world of woodworking because it is a very durable wood that is resistant to termites and rot. It is also easy to work with, especially for experienced woodworkers who know how to prevent tear-outs.

Although it has a unique red color, African padauk can darken over time due to its natural characteristics. With some wood finish, you can prevent some of this darkening.

This wood is very popular among woodworkers due to its strength, stability, and longevity. It can be used for furniture, household tools, and even musical instruments.

Is Padauk Good For Cutting Boards?

A good cutting board should be hard, dense, and heavy enough to remain stable on any countertop while you chop and slice. That’s why hardwoods are often used for cutting boards because they are easy to clean, odorless, and will not dull your knife.

After learning more about padauk, you have probably figured out that this is a great option to make cutting boards. It is extremely durable and is resistant to rot and damage. It can also maintain its shape over time, even after a lot of abuse in the kitchen.

If you are planning on making a cutting board out of wood, then you should know that padauk is the one for you. Let’s learn a bit more about padauk’s characteristics that make it an ideal candidate for making cutting boards.

Color

If you are a passionate woodworker, then the color of the wood that you use for your cutting board should matter to you. If something is displayed proudly in your kitchen, its color is definitely a huge aesthetic advantage.

Not all woods can offer the same natural beauty, but with the right amount of care, padauk wood can truly shine. Padauk comes in various shades, but most of the time, its deep red-orange tone makes it stand out.

Note that padauk does tend to oxidize a bit, especially when it is exposed to UV lights, so after a few years, you will see that the color becomes a bit darker than it was originally designed. You can use a wood finish to minimize some of this effect.

The change in color really doesn’t affect any other aspect of the wood’s performance, like its durability, so if you don’t mind the aged look, there’s really no reason to worry about the discoloration.

After a few years, the padauk will turn into a deeper brown color while retaining its natural wood grain and other natural characteristics.

Durability

Even if your wood has the most stunning color, if it is not strong enough to maintain its beauty over time, it probably won’t last very long in your kitchen.

When it comes to making a cutting board, it is important that the wood has good durability and can withstand the beatings of kitchen tools and knives. If not, you’ll end up having to throw the cutting board away after a few months!

Padauk is a hardwood, so it is very strong and can take the beating that comes from the kitchen. Because of its superior durability, the wood will not break, warp, or crack.

Because it can last for a long time without losing its shape and performance, there’s really no question about padauk wood’s longevity, which means you really get good value for money when investing in this option.

Rot Resistance

Because your cutting board needs to be washed on a daily basis (or however often you use it), the ability to resist rot and molds is extremely important.

You’ll be glad to know that padauk wood is also extremely resistant to pests and termites that can cause rotting. Aside from being rot-resistant, padauk wood can also resist decay, which is a huge reason why it can last for very long in your kitchen.

Padauk also has great stain-resistant abilities, which makes it really easy to keep clean. Since you’ll be with all kinds of food in your kitchen, you’ll be glad to know that the cutting board can stay fresh and new no matter what food you’re cutting up.

This is a key reason why padauk is a great option for cutting boards since it can withstand all the beatings from your kitchen and won’t be damaged when you put it in the dishwasher!

Workability

When it comes to choosing a type of wood for your project, woodworkers will always opt for the one that is not only suitable but also easy to handle.

Not everyone is planning on creating their own cutting board. However, if you are, then using padauk wood is a great way to ensure you’ll have a very easy time working with it.

This wood has a straight grain that can sometimes be interlocked, which makes it a bit harder to cut and easy to see tear-outs, but it’s nothing that a skilled woodworker can’t fix. Its coarse texture makes it easy to grip when cutting. Gluing and screwing the piece together also wouldn’t be a big issue.

Using padauk wood can help you create the perfect cutting board. Its grain pattern and overall texture can make the project go so seamlessly, and you’ll be sure to have a great result with some basic woodworking skills.

How Long Does Padauk Last?

As we’ve mentioned, padauk is a very strong, durable wood even if you use it for a cutting board and wash it every day, its ability to resist rot and wear and tear means that it can last for years in your kitchen.

There’s only one disadvantage when it comes to using padauk. Although it’s a great material for making cutting boards, the color of its wood will darken over time. When it’s exposed to sunlight, your padauk cutting board will most likely be affected by the UV rays and become discolored.

Over time, padauk wood will turn into a deep reddish-brown color. While this doesn’t really affect the wood’s performance, if you don’t like the discoloration, you can use a UV-protective wood finish to prevent this from happening.

Finishing Padauk Wood

Padauk wood naturally comes with so many great characteristics that are suitable for making cutting boards. You may think that using a wood finish is probably not necessary when it comes to padauk wood, but you may want to consider providing some extra protection to help the cutting board perform better.

Wood finish is usually a solution that protects wood from water damage and rot, helping to protect the wood from the inside. However, finishing padauk is not absolutely necessary since it already has some natural water-resistant and rot-resistant properties.

In the case of padauk wood, some woodworkers still choose to finish it with wood oil to protect it from discoloration.

As we’ve mentioned, padauk wood can become discolored over time, turning into a darker brown color and losing its distinct reddish color. If you don’t like this discoloration, you can opt for a wood finish that has some UV-protective abilities.

Because you are making a cutting board, it’s very important to use a food-safe finish and let the oil cure completely before using your cutting board with food.

While there are a few types of food-safe wood finishes, for padauk wood, using pure Tung oil or Raw Linseed Oil are usually the best options.

Pure tung Ooil can turn the wood color a bit darker, but this color will remain consistent over time and won’t change. However, Tung oil can be a bit difficult to apply and will require a few coats, so it’s a bit of a hassle to work with.

Raw linseed oil will also turn the color of padauk a bit darker, although not as dark as the effects of Tung oil, so you’ll still get the signature padauk appearance. Raw linseed oil does take a long time to cure (even up to a month) and requires to be re-finished after a few months, so you can still consider if it’s worth it to use this option.

Up Next: Is Poplar Wood Good To Use For Furniture?